Trenchless technology refers to a variety of methods used for installing and replacing underground utilities, such as water, sewer, and gas lines, without the need for extensive excavation. This approach has revolutionized the installation and maintenance of sewer systems by minimizing surface disruption, reducing repair time, and being more environmentally friendly than traditional trench digging methods.

The Benefits of Trenchless Sewer InstallationThe seamless nature of trenchless sewer installation provides numerous advantages over conventional methods. One of the primary benefits is the significant reduction in ground disturbance, which preserves landscaping, driveways, and roads. This not only saves on restoration costs but also reduces the impact on the community and environment. Additionally, trenchless methods are often quicker and more cost-effective, as they require less labor and avoid extensive traffic disruptions.

Safety is another key advantage, as trenchless installations reduce the risks associated with open trenches, such as cave-ins and traffic-related accidents. Moreover, trenchless technology tends to have a smaller carbon footprint since it requires fewer machinery and lessens the need for transporting and disposing of soil.

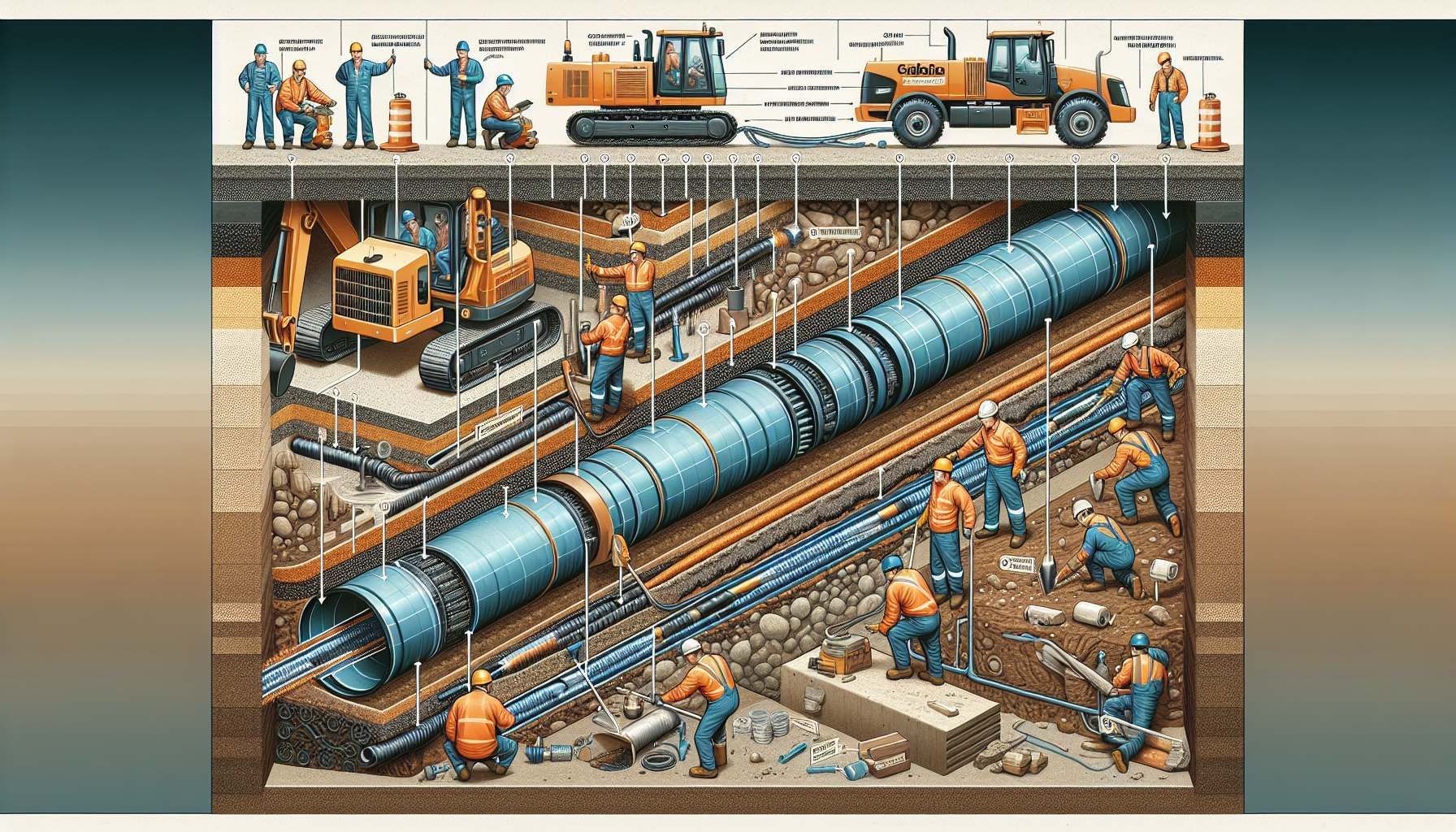

Key Trenchless Sewer Installation TechniquesThere are several trenchless techniques used for sewer installation, each suitable for different situations.

[LIST]

[*]Cured-in-Place Pipe (CIPP): This method involves inserting a resin-saturated felt tube into the existing pipe. Once in place, the resin is cured using hot water, steam, or UV light, creating a new, seamless pipe within the old one.

[*]Pipe Bursting: This process replaces an existing pipe by breaking it apart and immediately pulling a new pipe into place behind the bursting head. This is particularly effective for upgrading pipe sizes or replacing severely damaged pipes.

[*]Horizontal Directional Drilling (HDD): HDD is used to install new pipelines by drilling a pilot hole along a predetermined path and then enlarging the hole to pull through the new pipe, without disturbing the ground above.

[/LIST]

Each of these techniques requires specialized equipment and skilled operators to ensure successful installation and minimum environmental impact.

Challenges and ConsiderationsWhile trenchless technology has its advantages, it also comes with its own set of challenges. One of the primary concerns is the potential for unknowingly damaging existing underground utilities during installation. To mitigate this, thorough pre-installation investigations, including utility mapping and soil testing, are essential.

The condition of the existing sewer line also plays a critical role in determining the suitability of trenchless methods. Some techniques may not be appropriate for severely collapsed or misaligned pipes, requiring alternative methods or localized excavation to address these issues.

Training and ExpertiseThe successful application of trenchless technology depends heavily on the skill and knowledge of the operators. Proper training is vital to master the complex machinery and to make informed decisions on the spot. As such, investing in certified training programs and continuous professional development for workers is crucial for any company looking to excel in trenchless sewer installation.

The Future of Sewer InstallationWith urban areas becoming more congested and the increased emphasis on minimizing ecological disturbances, trenchless technology is set to become the standard method for sewer installation and rehabilitation. Innovations in materials, techniques, and machinery continue to evolve, aiming to make the processes even more efficient and versatile.

Authorities and utility companies are recognizing the clear advantages of trenchless methods, leading to a growing demand for skilled professionals in the field. By mastering trenchless technology, the construction industry can provide seamless sewer installation services that meet the modern demands of efficiency, safety, and sustainability.