Trenchless liner technology, often referred to as Cured-in-Place Pipe (CIPP) or simply trenchless technology, is a method for repairing and renewing existing pipelines without the need for extensive excavation. This innovative technique allows for the rehabilitation of pipes by creating a new, seamless pipe within an old, damaged one. It is an efficient and cost-effective solution for maintaining underground infrastructure with minimal disruption to the above-ground environment.

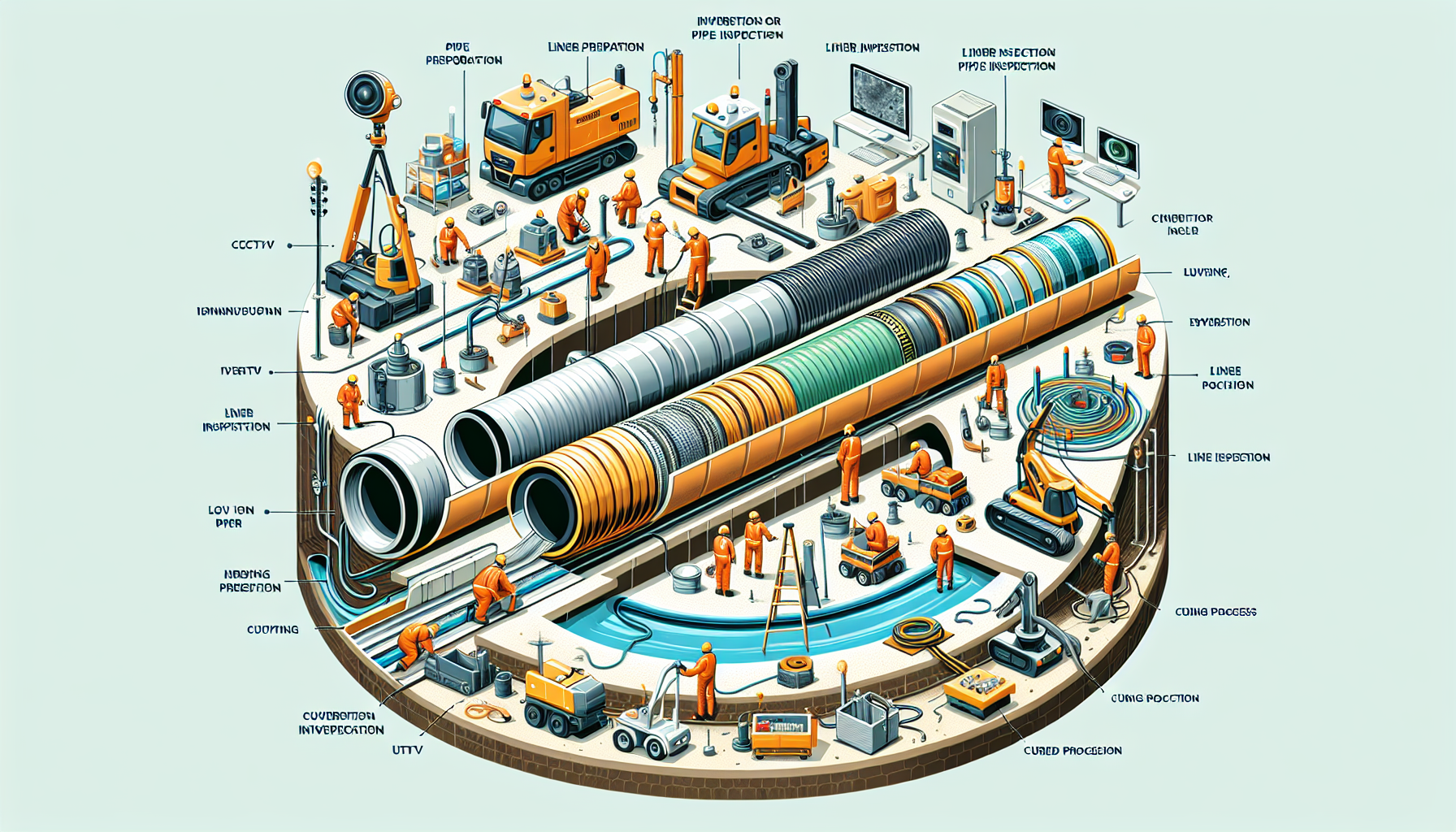

How Trenchless Liner Technology WorksThe process begins with the assessment of the existing pipe to determine suitability for trenchless repair. Once deemed appropriate, the pipe is cleaned and inspected to ascertain its condition and the extent of the damage. A flexible liner made from a felt or fiberglass cloth and impregnated with a thermosetting resin is then inserted into the damaged pipe.

This liner is usually inserted using one of two methods: inversion, which uses water or air pressure to invert the liner through the pipe, or winching, where the liner is pulled into place. Once the liner is correctly positioned, it is cured using hot water, steam, ultraviolet light, or ambient curing methods. This curing process causes the resin to harden, effectively creating a new pipe within the old structure. The hardened liner adheres to the interior of the existing pipe, sealing any cracks or breaks, and resisting corrosion and root intrusion.

Advantages of Trenchless Liner TechnologyThe advantages of trenchless liner technology are numerous and significant. Firstly, it vastly reduces the need for disruptive and costly excavation work. This means less traffic disruption, noise, and disturbance to the public and environment. Additionally, it is generally quicker and more cost-effective than traditional pipe replacement methods.

Trenchless technology is also more flexible than conventional methods, as it can be used in a variety of pipe diameters and types, including water, sewer, and gas pipelines. The resulting liner is smooth and durable with a life expectancy equivalent to that of new pipes. It also improves flow capacity and efficiency due to its smooth interior surface.

Environmental Impact and Safety ConsiderationsWith a growing awareness of the impact construction work has on the environment, trenchless liner technology provides a greener alternative to traditional open-cut methods. It limits the disturbance to the surrounding soil and ecosystems and reduces the carbon footprint associated with transporting and handling large amounts of excavated material.

As for safety, trenchless technology helps to minimize risks associated with deep trench excavations, such as cave-ins and damage to existing underground utilities. It also reduces the potential for accidents and injuries to workers and the public when compared to traditional construction methods.

Challenges and LimitationsWhile trenchless technology is versatile, it is not without its challenges and limitations. The initial cost of equipment and materials can be high. There are also limitations based on the condition and configuration of the existing pipe. Severely collapsed or misaligned pipes might not be suitable for lining.

The success of the method also relies heavily on the quality of the installation and curing process. Improper installation can lead to liner failures, such as wrinkles or folds, which can negatively affect the performance of the renewed pipe.

ConclusionTrenchless liner technology represents a significant advancement in pipeline repair and rehabilitation. It offers a less intrusive, more sustainable, and often more cost-effective alternative to traditional pipe replacement methods. Despite some limitations, the benefits of this innovative approach are compelling, making it a preferred choice for many utility companies and municipalities as they work to maintain and improve their aging infrastructure. As techniques and materials advance, trenchless liner technology will likely continue to evolve, further enhancing its application and efficacy in the field of underground utility management.