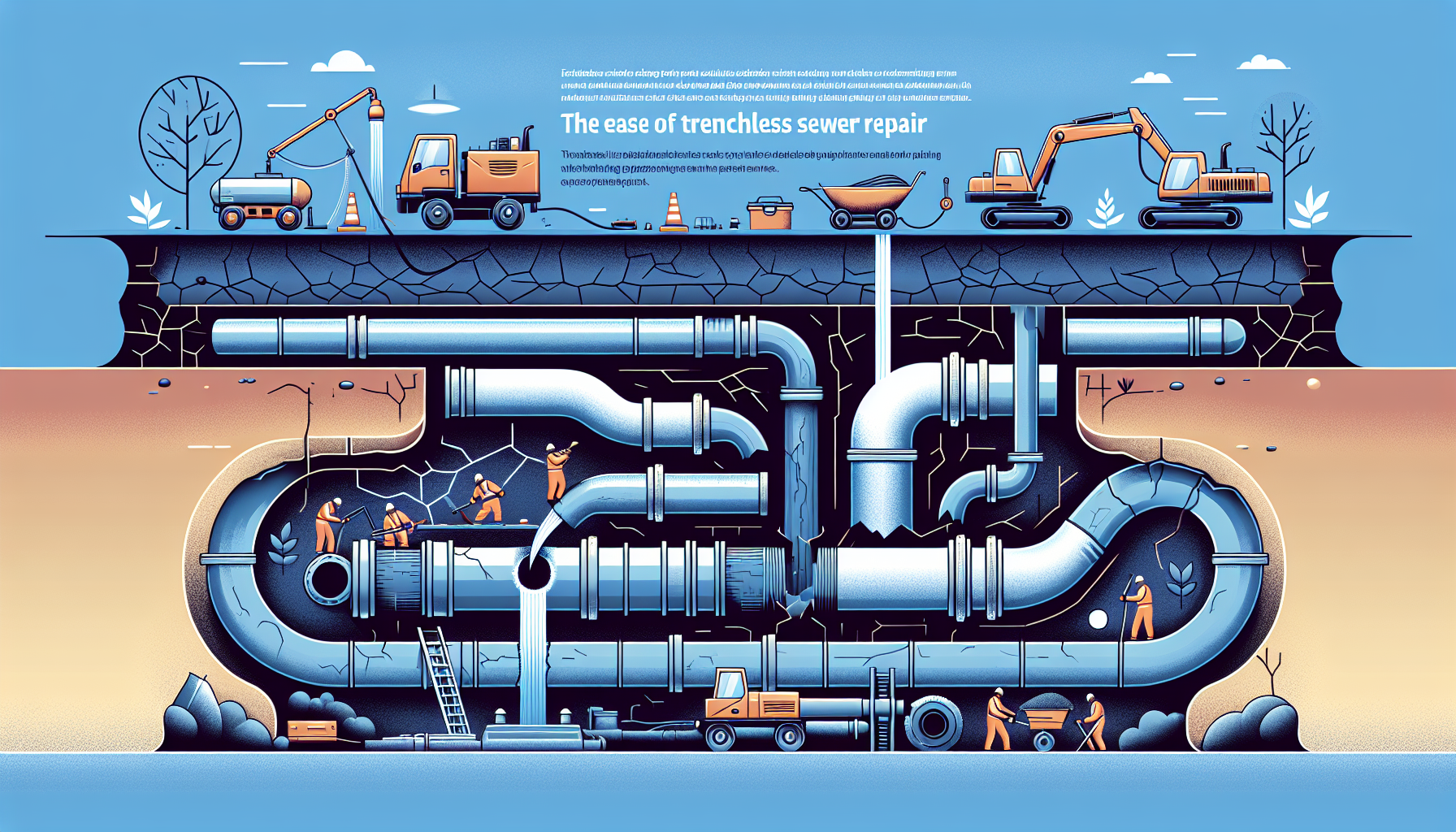

Introduction to Trenchless Sewer Repair

Trenchless sewer repair is a modern solution for repairing sewer lines without the need for extensive excavation. This innovative approach has revolutionized the plumbing industry, offering homeowners and city managers a less invasive, quicker, and often more cost-effective option for fixing damaged sewer pipes. One of the pioneers of this technology is Dan Colbert, who champions the ‘no-dig’ method to streamline the process even further.

Understanding No-Dig Technology

The no-dig technology relies on methods such as pipe lining and pipe bursting. Pipe lining, also known as cured-in-place piping (CIPP), involves inserting a resin-coated flexible tube into the damaged pipe, which is then inflated and cured to form a solid, seamless pipe within a pipe. On the other hand, pipe bursting replaces the old pipeline by fracturing it outward while drawing in a new pipe of the same or larger diameter.

Benefits of Colbert’s No-Dig Solution

Colbert’s no-dig solution comes with a multitude of benefits that stand out against traditional trenching.

1. Minimal Disruption

One of the most significant advantages is the minimal disruption to the landscaping, hardscaping, and general activities on the property. Since there’s no need to dig a trench, the damage to gardens, pathways, and driveways is significantly reduced, if not entirely eliminated.

2. Cost Efficiency

Trenchless methods can be more cost-effective in the long run. The costs associated with digging, including labor and heavy machinery, are minimized. Additionally, the lack of excavation reduces the need for costly restoration work post-repair.

3. Time Savings

The efficiency of trenchless sewer repair translates into significant time savings. While traditional repairs may take days or even weeks, the no-dig solutions can often be completed in a day or less, quickly restoring service and reducing inconvenience.

4. Environmental Responsibility

Avoiding large-scale excavation means less soil disturbance and a reduced carbon footprint from heavy machinery. It also reduces the risk of contamination and runoff that can result from exposing a large area of soil during traditional sewer repair work.

5. Durability

Trenchless repairs result in durable pipes with a lifespan comparable to, or even exceeding, that of new traditional pipes. Materials used in no-dig repairs are resistant to corrosion and tree-root intrusions, contributing to the long-term integrity of the sewer system.

The Process of Trenchless Sewer Repair

Colbert’s no-dig solution follows a systematic process. First, the affected pipes are identified through a sewer camera inspection. Once the damage is assessed, the appropriate trenchless method is chosen. The area around the entry and exit points is cleared, but with minimal surface disruption. The no-dig repair is then carried out, followed by a final inspection to ensure the integrity of the new pipe.

Choosing The Right Professional

It’s essential to select a professional experienced in Colbert’s no-dig trenchless sewer repair. Proper training and the right equipment are crucial for a successful application of this technology. When hiring a contractor, ask about their experience with trenchless repairs, their equipment, and see if they can provide references or case studies of their previous work.

Conclusion

Colbert’s no-dig trenchless sewer repair offers an attractive alternative to traditional methods. The ease of this repair technique, combined with its array of benefits, has made it a go-to for those seeking to fix sewer problems efficiently and effectively. As this technology becomes more widespread, it’s likely that more companies will adopt Dan Colbert’s approach, making trenchless repairs the new standard in the industry.